FulltimeRobotics, a construction robotics company, has recently announced the completion of a tens-of-millions strategic investment round led by Century Golden Source. Previously, the company had secured a pre-A round of tens of millions of financing exclusively from Kunzhong Capital.

Founded in May 2022, FulltimeRobotics focuses on the research, development, production, and sales of construction robots. The company has positioned itself as a leader in the niche market of painting construction robots. Its product portfolio covers a range of applications, including putty spraying, scraping, grinding, dust collection, and latex paint spraying. The robots can increase putty construction efficiency to 1,000-1,200 square meters per day, which is 8-10 times the efficiency of manual labor. For latex paint spraying, the robots can achieve an efficiency of 3,000 square meters per day, doubling the efficiency of handheld spray machines. Additionally, the robots can precisely control material usage and ensure even application, resulting in a material cost savings of 20%-25%.

The company's founder and CEO, Li Zike, brings 17 years of experience in the construction technology industry. He previously served as the vice president of a construction information technology company listed on the STAR Market and has extensive experience in product operations and commercial promotion. The construction and BIM software he led in developing and commercializing currently hold a leading position in the market.

The shortage of labor in the construction industry in developed countries overseas is becoming increasingly acute, while the aging of the workforce in China's construction industry is also a growing concern. According to data from the National Bureau of Statistics, the average age of construction workers in 2023 was 43.1 years old, with over 50% being above 50 years old. As economic development and living standards improve, the harsh working conditions on construction sites make it even more difficult to attract young labor, creating a vicious cycle of labor shortages.

Market demand and policy requirements are forming a dual push to accelerate the transformation and upgrading of the construction industry. The Ministry of Housing and Urban-Rural Development's "14th Five-Year Plan for the Construction Industry" explicitly requires the "acceleration of the research and application of construction robots." It emphasizes the need to strengthen core technologies such as new sensors, intelligent control and optimization, multi-robot collaboration, and human-robot collaboration. The plan also calls for the active promotion of construction robots in production, construction, and maintenance, with a focus on applications that support prefabricated construction. This initiative aims to replace and assist in hazardous, labor-intensive, dirty, and heavy construction work. Additionally, the "Notice on the Announcement of Smart Construction Pilot Cities" has selected 24 pilot cities, including Beijing and Baoding, to implement smart construction pilot projects, with construction robots being one of the six key tasks.

Against this backdrop, construction robot technology has emerged as a solution. By integrating BIM and visual recognition with robotic technology, construction robots not only improve construction quality but also achieve standardized and efficient construction without the physical limitations of traditional workers. This technology not only brings a qualitative leap to the industry but also provides the necessary support for the transformation and upgrading of the construction industry, optimizing the construction environment and adjusting the structure of construction workers to attract labor back to the industry.

Painting engineering is characterized by high standardization, continuous working surfaces, minimal interlocking processes, and a large market space, making it a potential niche market for the first large-scale application of construction robots. Statistics show that the total construction cost for painting projects in China's residential, commercial, and public buildings, as well as urban renewal, is around 500 billion yuan annually. In major developed countries overseas, the construction cost for painting projects is close to 100 billion US dollars. According to the latest spraying robot supplementary quota statistics in China, robots account for 40% of the total cost as mechanical fees, indicating a vast market potential.

Based on data from the 24 national smart construction pilot cities, painting construction robots are almost a mandatory option for the application of construction robots. Many localities require construction companies to have explicit robot subcontracting agreements, which will accelerate the promotion and popularization of painting construction robots.

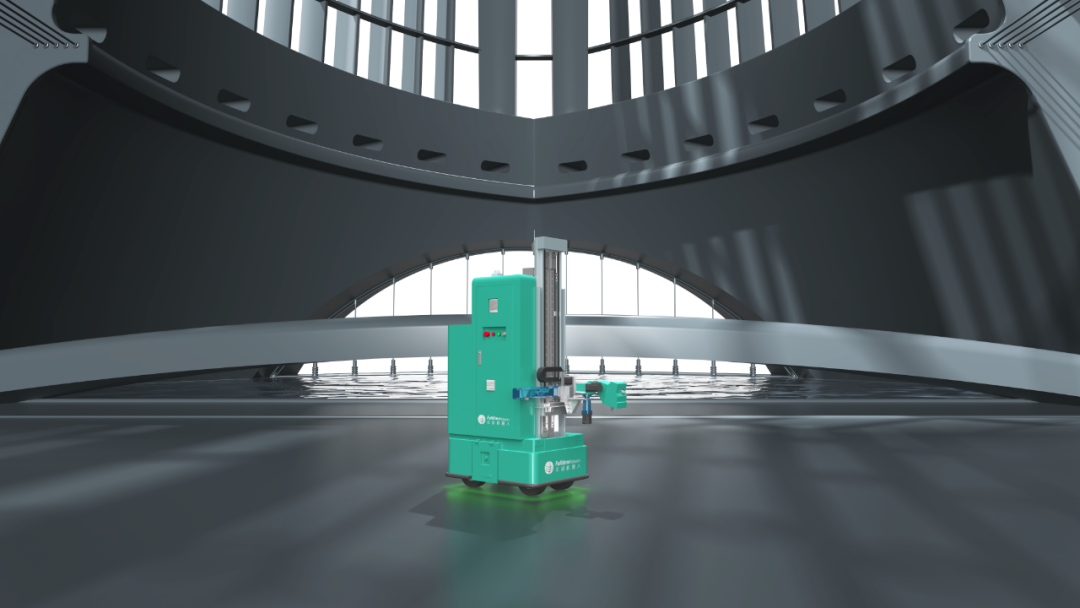

3.2-meter Spray-Painting Robot

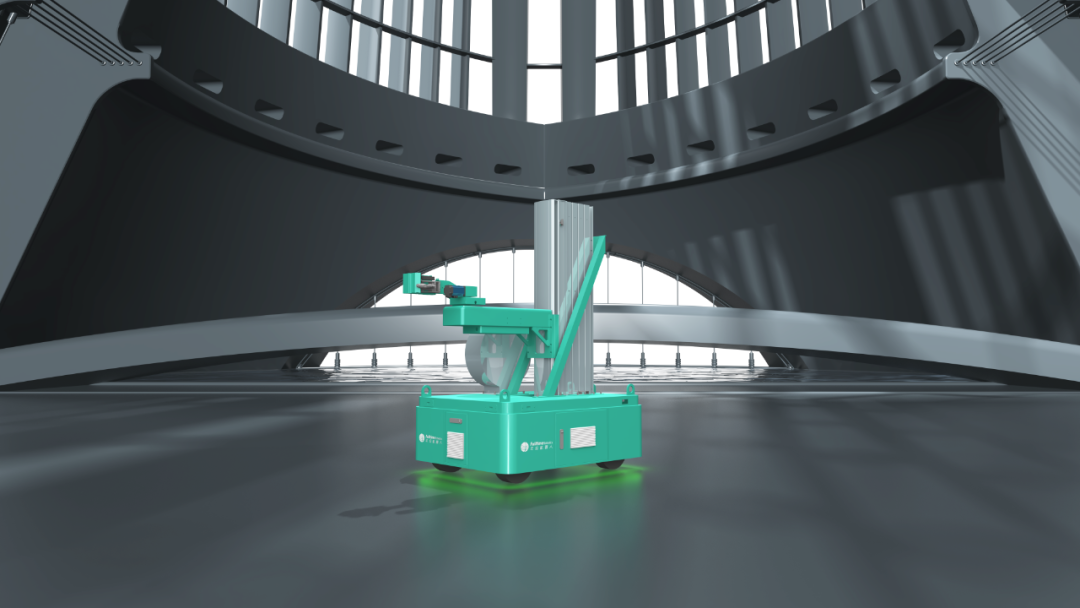

6-meter Spray-Painting Robot

According to Xu Anpeng, the CTO of FulltimeRobotics (former president of the Decoration Robotics Research Institute at Boticellin), the company uses 3D point cloud, robotics, and artificial intelligence technologies to digitize traditional construction processes and integrate them into the robot's process library, continuously improving and iterating in practical operations. The company also employs multi-technology integration in spatial automation, such as AI visual recognition and normal compensation motion control, to handle complex construction site environments and assist or replace traditional painters.

"In the future, we will continue to innovate around customer needs, especially in the international market. Taking Singapore as an example, the putty used locally is more viscous, requiring us to conduct targeted research and development in nozzle design, spray gun, pressure control, and spraying motion to adapt to local materials and processes. Additionally, we will increase our R&D investment in automated construction. By automatically collecting room data, intelligently optimizing work paths, and positioning navigation, we will further improve the efficiency and quality of automated construction in residential projects," said Xu Anpeng.

Currently, FulltimeRobotics' products have achieved small-scale mass production, with a cumulative construction area exceeding 500,000 square meters. The company has successfully applied its robots in multiple projects worldwide. Through direct sales and channel cooperation, FulltimeRobotics targets public construction projects such as industrial parks, schools, hospitals, and stadiums, as well as commercial buildings, selling robots to construction and leasing companies. In overseas markets, the company mainly focuses on Singapore and Europe, developing small multi-angle spraying robots suitable for narrow spaces.