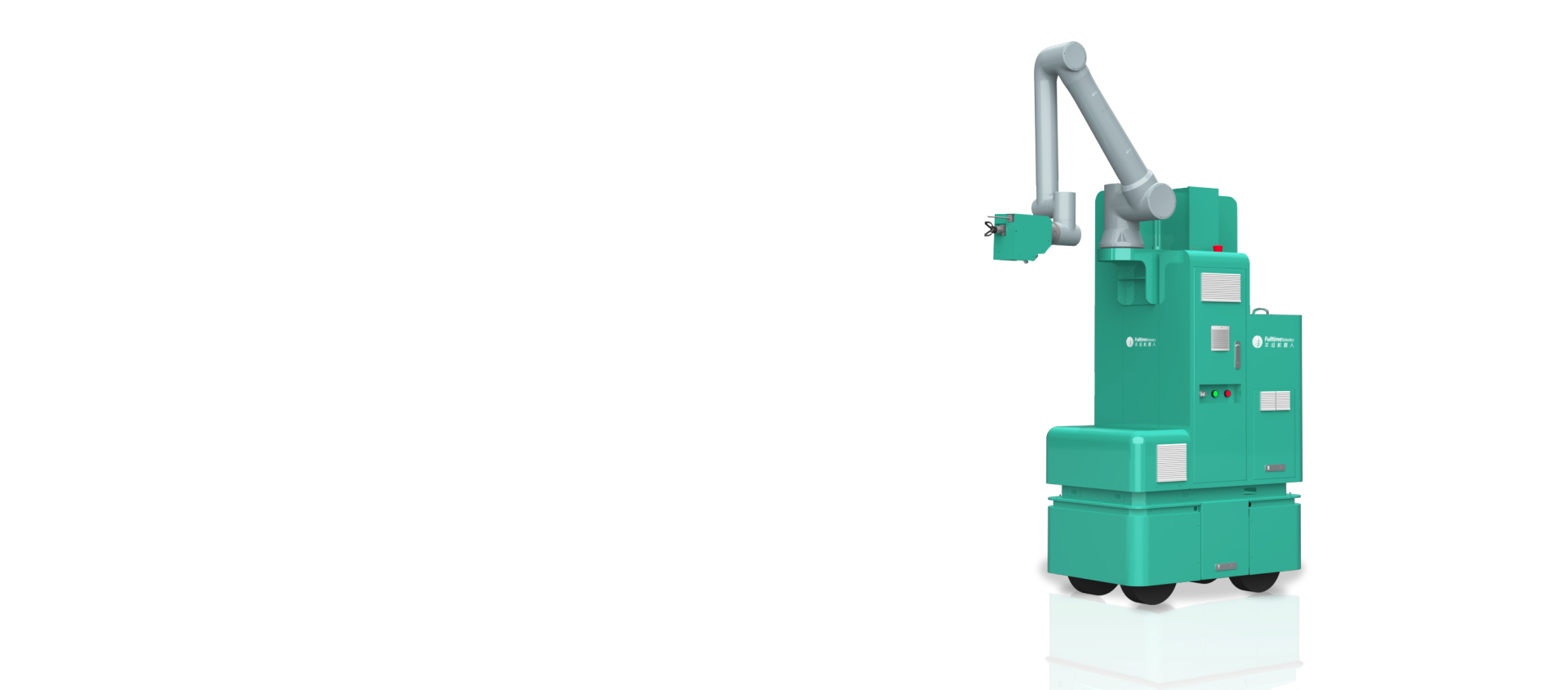

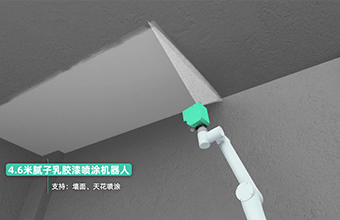

4.6-meter Spray-Painting Robot

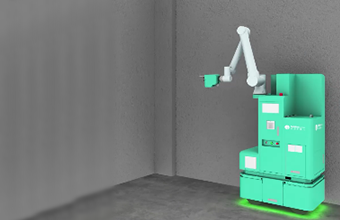

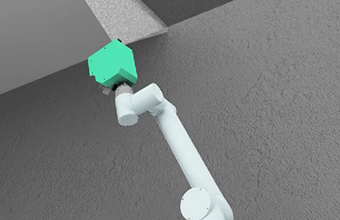

The 4.6-meter model of the spraying robot is suitable for scenarios with a height of less than 4.6 meters, such as commercial complexes, office buildings, industrial parks, hospitals, schools, hotels, venues, basements, etc., and can complete surface construction of walls, ceilings, beams, columns, internal and external corners, etc.

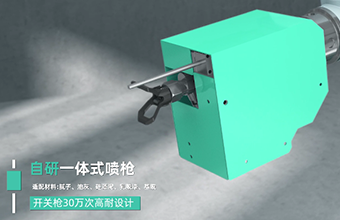

The 4.6-meter model of the spraying robot has the feature of multi-functionality. By quickly replacing the nozzle, it can achieve spraying of multiple materials, including water-based materials such as latex paint, putty, oil putty, anshi powder, volcanic mud, etc.

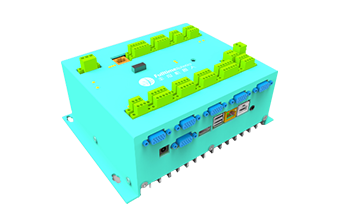

With self-developed intelligent control systems and high-quality spraying process technologies, the 4.6-meter model of the spraying robot can achieve uniform coating coverage, improving construction quality and efficiency. It can work quickly and efficiently for both large-area painting and detailed treatment, significantly saving construction time and costs.