From June 24th to 25th, the 2025 Hangzhou Intelligent Construction Innovation Development Promotion Conference and Innovation Week, hosted by the Hangzhou Municipal Construction Commission and the Hangzhou Construction Industry Association, was successfully held in Hangzhou. Focusing on core topics such as intelligent construction technologies and digital transformation of the construction industry, the event gathered cutting-edge technological achievements, innovative thinking, and practical experiences in the industry, building a high-quality platform for technical exchanges and win-win cooperation among enterprises.

Li Zike, Founder and CEO of Fontan Robotics, was invited to participate in the technical exchange meeting of the Innovation Week and delivered a keynote report titled "Innovation in Application and Organizational Models of Construction Robot Projects". He shared Fontan Robotics' construction robot solutions covering the full business scenarios and construction processes in the coating engineering construction field, as well as their practical applications in multiple important projects at home and abroad.

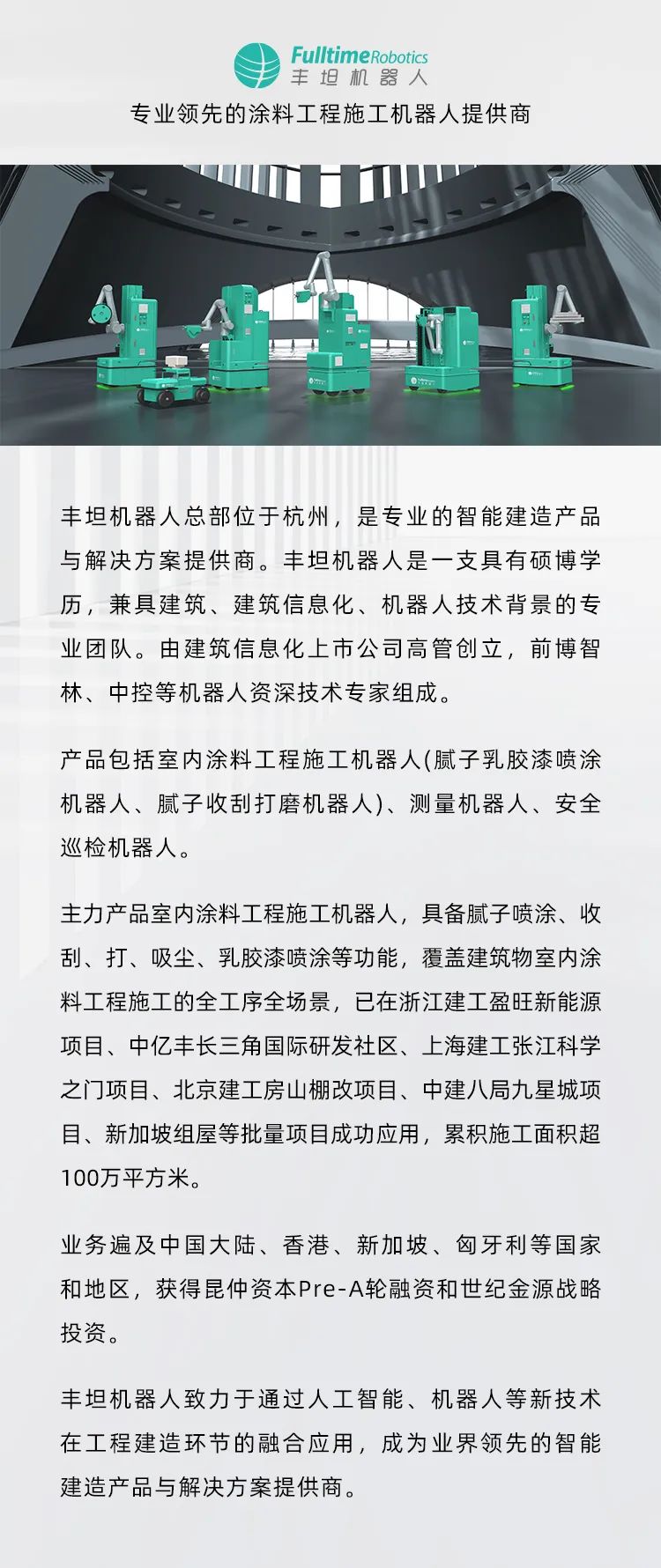

With the mission of achieving global customer success through intelligent construction, Fontan Robotics is committed to becoming a leading intelligent construction product and solution provider in the industry through the integrated application of new technologies such as artificial intelligence, BIM, and robotics in the engineering construction sector. Focused on indoor coating engineering construction robots, Fontan's construction robot solutions cover building robots for main structure construction, decoration, and auxiliary construction of housing, and use technologies such as 3D point cloud, high-precision laser positioning, high-precision servo control, and motion control to assist and replace traditional putty and latex paint construction operations by painters.

Li Zike stated that Fontan Robotics has covered the full processes of paint construction, including putty spraying, scraping, grinding, dust collection, and latex paint spraying. It has functions such as path planning, automatic navigation, obstacle avoidance, and uniform spraying, with obvious advantages in construction efficiency, quality stability, and material saving. The Fontan third-generation coating robot P320 Max, released in May this year, is based on the demand for whole-house automated construction in residential engineering projects, innovating the intelligent construction experience.

Up to now, Fontan Robotics has been batch-applied in important projects such as Zhejiang Construction Investment Hangzhou Construction Home, Zhejiang Construction Yingwang New Energy Precision Structural Parts, Shanghai Construction Zhangjiang Science Gate, Beijing Construction Haidian Yongfeng, and Singapore Tengah Prac Residences, with a cumulative construction area exceeding 1 million square meters.

At the event site, the Fontan spraying robot P320 Max and safety inspection robot debuted stunningly in the technical exchange area, attracting many attendees to stop and pay attention. Focused on whole-house intelligent construction, the P320 Max is tailor-made for indoor coating construction scenarios below 3.2 meters. It is widely applicable to various spaces such as residences, apartments, and hotels. With its excellent performance, it can accurately tackle construction challenges in complex areas such as walls, ceilings, corners, bay windows, and entrances. The latex paint spraying efficiency is as high as 250㎡ per hour, significantly shortening the construction period and greatly reducing labor costs.

The safety inspection robot can act as a 24-hour safety guard. Using technologies such as laser navigation, path planning, and artificial intelligence visual recognition, it can intelligently set the inspection route map of the construction site and accurately identify personnel's non-compliant operations and equipment safety hazards. It not only improves management efficiency but also completely retains data, building a technological defense line for construction safety management.

As the Vice President Unit of the Intelligent Construction Branch of the Hangzhou Construction Industry Association, Fontan Robotics has always taken technological innovation as the core driving force and led the intelligent transformation of the construction industry with an international perspective. In the future, Fontan will continue to deepen strategic cooperation with industry peers. Through multi-level technical exchanges and cross-domain experience sharing, it will join forces with various member units to contribute wisdom and strength to the development of intelligent construction in Hangzhou and the whole country, and work together to open a new chapter of high-quality development in the construction industry.

咨询联系

万先生 138 6800 4977